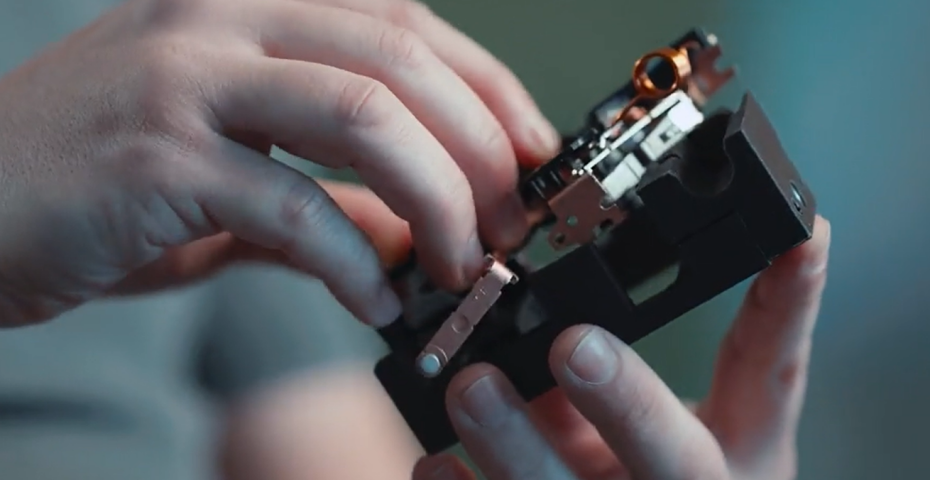

Schneider Electric, a global leader in energy management and automation, has been committed to optimize resources and enhance efficiency for over 100 years. At their smart factory in Plovdiv, Bulgaria, the company focuses on producing high-quality electrical components, including the essential Miniature Circuit Breaker (MCB), which ensures safe and reliable electrical systems by protecting circuits from overcurrents and short circuits.

To streamline production and reduce lead times, Schneider Electric integrated Additive Manufacturing (AM) and Fused Filament Fabrication (FFF) technologies into their 3D printing farm a few years ago. In October 2024, the adoption of the INTAMSYS FUNMAT PRO 310 NEO marked a significant upgrade, enabling in-house production of key components and improving overall workflow efficiency.

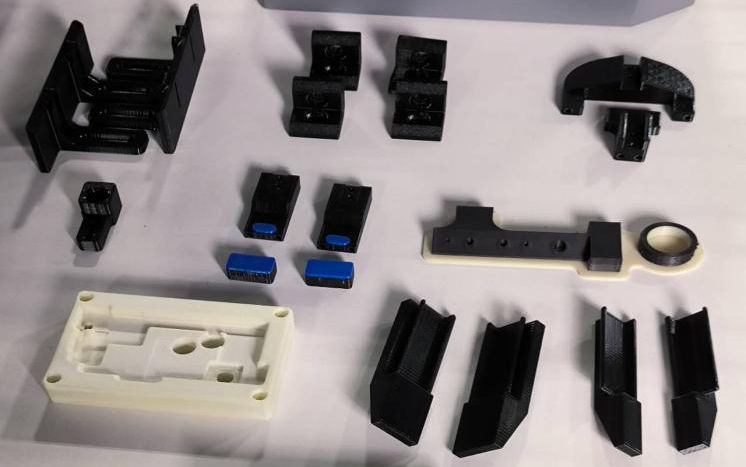

By adopting 3D printing technology, the facility can now manufacture all the mechanical components required for its production line in-house. The FUNMAT PRO 310 NEO has played a crucial role in this transformation, primarily being used to print jigs and fixtures, which has significantly improved workflow efficiency. The 310 NEO is used with a wide range of materials, including PC, PA6, PA12, PPA, PA6-CF and PPS, enabling the production of durable and high-quality parts.

We accompany our customers in a professional manner throughout the entire project - from planning and design to the prototype or the production of a complete series. Combining our 3D printing processes with conventional component processing, post-processing and surface refinement of the prototypes, small series or even a trade fair exhibit is our daily business. Since the company was founded in 1995, our experienced team in Gross-Gerau has made a name for itself well beyond the borders of the Rhine-Main area. We are one of the leading service providers for everything to do with 3D printing and have more than satisfied customers from a wide variety of industries - from the automotive and consumer goods industries to mechanical engineering and companies from the medical technology sector.

Alex Di Maglie

Managing Director, 4D Concepts

Prior to implementing the FUNMAT PRO 310 NEO, Schneider Electric faced inefficiencies due to conventional manufacturing methods and slower 3D printing solutions. Producing functional prototypes and custom parts took too long, often creating bottlenecks in the development process. Injection molding further extended lead times, sometimes delaying production for up to three weeks or longer. The company needed a faster, more reliable solution to accelerate part production and improve workflow efficiency.

Schneider Electric selected the INTAMSYS FUNMAT PRO 310 NEO for its high-speed capabilities, material compatibility, and industrial grade performance. With the ability to print parts in just two hours, compared to the 12 to 15 hours for the same part, the 310 NEO drastically accelerates production cycles.

The printer’s automatic bed leveling and heated chamber (capable of reaching 100°C) simplify setup and ensure consistently high print quality. The high chamber temperature is particularly advantageous for engineering materials like PC, preventing warpage in full-size prints and providing higher Z-strength for enhanced mechanical performance.

Additionally, its open material system provides flexibility to work with various materials, though Schneider Electric primarily uses INTAMSYS filaments due to their optimized profiles and superior print consistency.

We prefer to use the materials produced by INTAMSYS because INTAMSUTE NEO slicing software has already built-in, optimized profiles that ensures perfect prints every single time.

Kamen Vasilski

Maintenance Engineer at Schneider Electric

IDEX Technology

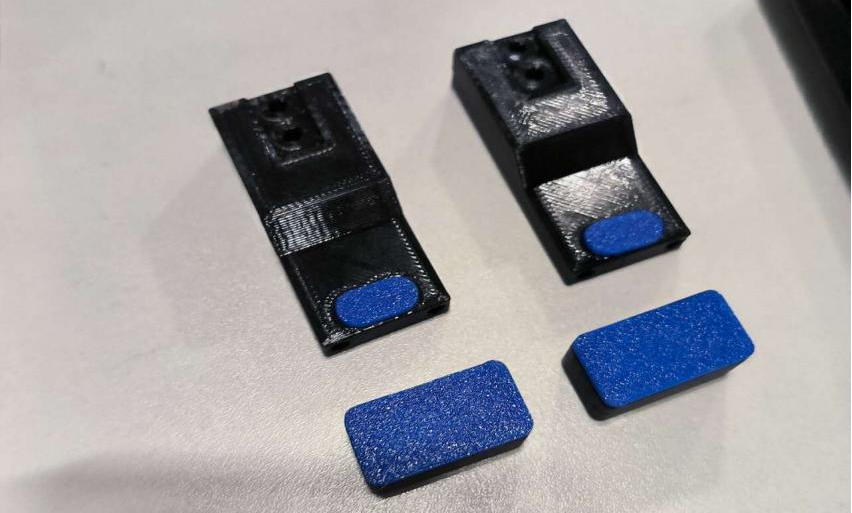

The 310 NEO’s IDEX (Independent Dual EXtruders) technology enables Schneider Electric to print complex parts with multiple materials in a single print job. For example, the team designed a gripper with rubber-like properties to prevent parts from falling off production lines. By combining flexible TPU95A and structural PETG, they created a durable, high-quality component that facilitates smooth production.

Additionally, Schneider Electric uses IDEX technology to produce welding jigs with complex geometries for use inside their factory machines. By combining PA6-CF with soluble support material SP3030, they were able to create these parts in under six hours—far faster than traditional methods would allow.

Since integrating the FUNMAT PRO 310 NEO, Schneider Electric has seen a remarkable improvement in production efficiency. Key benefits included:

The adoption of the INTAMSYS FUNMAT PRO 310 NEO at Schneider Electric’s smart factory in Plovdiv, Bulgaria, has significantly enhanced efficiency, flexibility, and cost savings. The integration of 3D printing technology continues to drive innovation in the production of electrical components.

With their Smart Factory certification, Schneider Electric plans to expand its 3D printing farm to further increase in-house production of components and spare parts, further reducing maintenance costs and improving self-sufficiency.

This success highlights the transformative potential of 3D printing in modern industrial environments, proving that how the INTAMSYS FUNMAT PRO 310 NEO can redefine manufacturing processes for greater efficiency and innovation.

Most consumer-level FFF 3D printers cannot print brackets capable of supporting exceptionally heavy weights. Common filaments like PLA and ABS are durable enough for prototypes and low-impact applications, but it takes a much stronger material to guarantee high performance in the heat and humidity of Suriname.

During a military exercise in South America, crew members needed brackets to support a 20 kg signal amplifier so it could be mounted near the top of a 25-meter pole. This placement reduced the need for long cables and boosted the antenna signal. Without the necessary brackets on hand, the crew used an INTAMSYS printer to create them out of PEKK-CF, a high-performance material requiring extrusion temperatures of at least 350°C. Weaker materials would have buckled under the heavy weight and compromised safety.

A naval ship or submarine contains numerous valves for regulating pressure and fluid flows, controlling everything from fresh water to hydraulic systems. These valves have wheels that allow manual adjustments and are regularly removed for cleaning and maintenance. However, they sometimes break or get lost, necessitating spares.

Due to the diversity in valve wheel types and sizes, DMI workers have been using their INTAMSYS 3D printers to fabricate wheels on demand rather than carrying numerous prefabricated aluminum/steel spares. Valve wheels printed in high-strength materials are durable, resistant to overheating, and can even be installed permanently.

Ships and machines aren’t the only things that require maintenance on long missions. Crew members can suffer injuries in the field, and ships aren’t always within reach of a medical center.

DMI’s additive specialists have been collaborating with Radboud University Medical Center on a research project to develop custom orthotics. Using a mobile 3D scanning application developed by Belgian company Spentys, technicians can design and 3D print custom-fit orthotics to treat minor injuries. A variety of materials can be used, including PEKK, ABS, and PP. The devices can be adjusted over time with straps as the injury heals.

3D PRINTER

FUNMAT PRO 410

COST-EFFECTIVE

Print Larger, Print More

OPEN

Open-Sourced Filaments

©2026 INTAMSYS Technology. All Rights Reserved. Privacy Policy