近年来,PEEK(聚醚醚酮) 在人体硬组织替代物 3D 打印领域的应用引起了广泛关注。凭借优异的生物相容性和化学稳定性,以及与人体骨骼接近的密度和力学性能,PEEK 成为理想的骨替代材料,并逐渐发展为替代金属植入物和假体的核心候选材料,广泛应用于骨科、脊柱及颅颌面外科等领域。结合 3D 打印技术,PEEK 有望在骨科植入物领域实现更大规模的应用。

远铸智能与空军军医大学唐都医院联合开展的 PEEK 3D 打印先进医疗应用项目,正是该领域具有开创意义的实践探索。

在传统的颅骨植入手术中,通常采用坚硬且轻质的钛网来修复缺损或填补空隙。医学界一直在不断探索新的植入材料,以提升手术效果并改善患者的术后体验。

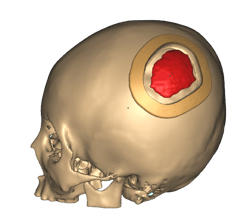

空军军医大学唐都医院的一名患者因头部肿瘤导致颅骨受损,需要进行颅骨植入修复。医生基于患者的 CT 扫描数据,使用 CAD 软件设计了“量身定制”的颅骨结构。随后,在 远铸智能 3D 打印技术的支持下,采用 FDM(熔融沉积成型) 工艺,使用高性能 PEEK 材料打印出定制化颅骨植入件。手术过程中,医生按照既定方案精准植入颅骨部件,成功修复了患者的颅骨缺损。术后检查显示,植入件与患者自身骨骼高度贴合、无成像伪影,患者术后恢复情况良好。

2018 年,唐都医院泌尿外科与空军军医大学 3D 打印研究中心联合完成了全球首例采用 3D 打印技术治疗胡桃夹综合征的手术,使用 PEEK 仿生材料制造人体植入物。随后,空军军医大学 3D 打印研究中心借助远铸智能的 FDM/FFF 3D 打印技术,在多例胸肋骨 PEEK 替代手术中实现突破,成功制备并应用了新型植入物。

截至目前,依托 3D 打印技术,已完成数百例 PEEK 植入手术,患者术后恢复情况良好。

.png?width=940&height=236&name=Nutcracker%20PEEK%20implant%203D%20printed%20by%20INTAMSYS%20equipment%20(1).png)

随着医疗植入物生产从传统的标准化大规模制造向患者个性化定制生产转变,3D 打印在医疗植入物制造领域中的作用日益凸显,使患者专属、小批量定制的 PEEK 植入物实现规模化生产成为可能。基于材料挤出成型工艺的 FDM/FFF 3D 打印技术,相较于传统制造方式,在小批量生产方面具备更高的性价比与效率优势。例如,在前述唐都医院的颅骨修复手术中,医疗团队正是依托远铸智能的 FDM/FFF 3D 打印技术,为患者“量身定制”了 PEEK 植入物,使颅骨植入件与患者自身骨骼高度贴合,显著促进了术后快速康复。

此外,借助增材制造/3D 打印技术在复杂结构制造方面的优势,还可在设计层面提升 PEEK 材料的生物活性。例如,通过 3D 打印可构建互连的一体化多孔结构,以促进 PEEK 植入物的骨整合,提高 X 射线成像准确性,并实现更接近人体松质骨的弹性模量。

制造设备与工艺稳定性是 PEEK 3D 打印医用植入物实现商业化应用的前提条件。由于 PEEK 具有较高的熔点,其加工过程需要进行高温热处理。同时,高加工温度与 PEEK 较高的结晶速率相叠加,容易产生过大的热应力(在打印层间分布不均),从而引发热裂纹,并导致 层间结合力不足、零件翘曲变形 等问题。因此,与工程塑料和通用塑料相比,PEEK 的 FDM/FFF 3D 打印工艺要复杂和严苛得多。要获得高质量的 PEEK 3D 打印零部件,必须依赖专用的制造工艺以及针对 PEEK 材料设计的 FDM 3D 打印设备。

从本质上看,高性能材料的 3D 打印是一种高温条件下的高分子材料热加工过程。合理的打印腔体热设计及合适的腔体温度控制,能够有效提升材料层间的结合强度,同时减少因冷却与残余应力带来的收缩和变形。不同材料在材料挤出式 3D 打印过程中,对腔体温度的要求各不相同,而高性能 PEEK 材料进行 3D 打印时,所需的腔体温度通常应达到 150–250°C。

以 远铸智能 FUNMAT PRO 610HT 高性能材料 3D 打印设备为例,该设备配备全封闭成型腔体,打印平台与腔体温度可在室温至 300°C 范围内精确控制。设备通过双侧循环热风管道对腔体进行加热,并与打印平台同步升温;腔体外部采用加厚保温层以降低热量散失。在达到预设温度并稳定一段时间后,腔体内整体温场高度均匀,温度可精准控制在 300°C ± 2.5% 的范围内。

凭借卓越的高温性能,远铸智能 FUNMAT PRO 610HT 主要用于 PEEK、ULTEM、PPSU 等高附加值材料的增材制造,并可满足市场上绝大多数 FDM/FFF 材料的 3D 打印需求。不同于仅依靠打印平台加热的普通 3D 打印机,FUNMAT PRO 610HT 能进一步确保打印件首层与平台的高强度粘附,并在整个打印过程中使材料始终处于均匀温度环境,从而有利于大尺寸样件成型,有效避免翘曲等缺陷,为 PEEK 材料的高质量 3D 打印提供了可靠保障。

无论是颅骨修复、胸骨修复,还是胡桃夹综合征的治疗,定制化植入方案都将以更高的精准度和效率,为患者带来更优的治疗体验与康复效果。同时,3D 打印技术也在骨重建、假体制造等其他医疗领域持续带来创新与突破。我们坚信,未来的医疗世界将见证 3D 打印技术所带来的无限可能。

Their in-house INTAMSYS Printers 3D printed parts have a unique application in carbon-fiber structures. To shape the carbon-fiber structures and prevent them from melting at high temperatures during the process, the team uses 3D-printed parts made from PEI material. The high strength and heat resistance of PEI make it suitable for the hot and pressurized environment inside an autoclave.

The team also uses PEI a lot inside their high-voltage accumulator. With its fire resistance and high strength abilities, PEI is again the perfect choice for many parts inside the accumulator. One of these parts is Air Geo, which is located inside the accumulator at the back of the car. This component serves as a housing for cables, relays, fuses, and numerous PCBs, ranging from light indicators for the accumulator to the accumulator management system.

After thorough research and benchmarking, WEERG chose INTAMSYS as their supplier. The INTAMSYS FUNMAT PRO 410 met all their requirements with features like a heated chamber, dual heated nozzles, and a heated filament chamber.

INTAMSYS offered one single solution that got it all:

We accompany our customers in a professional manner throughout the entire project - from planning and design to the prototype or the production of a complete series. Combining our 3D printing processes with conventional component processing, post-processing and surface refinement of the prototypes, small series or even a trade fair exhibit is our daily business. Since the company was founded in 1995, our experienced team in Gross-Gerau has made a name for itself well beyond the borders of the Rhine-Main area. We are one of the leading service providers for everything to do with 3D printing and have more than satisfied customers from a wide variety of industries - from the automotive and consumer goods industries to mechanical engineering and companies from the medical technology sector.

Alex Di Maglie

Managing Director, 4D Concepts

We were looking for printers that can print high-performance materials and run 24/7 on our production floor. INTAMSYS offered a robust printer, a nice aesthetic finish, and a true partnership.

Matteo

Founder & CEO, WEERG

Innovative thinking such as interdisciplinary and medical-industrial integration is a powerful means for the further development of clinical medicine, and medical 3D printing technology is such a sharp sword that can overcome practical clinical problems. I believe that in the near future, 3D printing technology will push the medical industry into an exciting new era.

Professor Cao Tiesheng

Tangdu Hospital

3D PRINTER

FUNMAT PRO 410

COST-EFFECTIVE

Print Larger, Print More

OPEN

Open-Sourced Filaments

INTAMSYS has sponsored the GreenTeam with a FUNMAT HT 3D printer, INTAM™ filaments, and consultation services. The 3D printed parts from INTAMSYS are used in various subsystems of the car, including the battery system, braking system, and power electronics.

3D PRINTER

FUNMAT HT

COST EFFICIENCY

Lower Cost, Shorter Lead Times

MATERIAL SUPERIORITY

Versatile INTAM™ Polymers

The tank holder is a new part in this year´s racing car. The part is printed on the FUNMAT PRO 610HT with the material choice of ABS. For the driverless disciplines, the team uses pressurized air to activate the brakes in an emergency. This year, they changed the concept of how pressurized air is stored, which required a new mounting solution. The tank holder is designed to solve this challenge.

.png?width=807&height=410&name=Flap%20Ribs%20(2).png)

Other 3D printed parts, using the FUNMAT PRO 610HT and PC material, are the flap ribs that play a crucial role in the construction of the car’s side wing. These ribs are glued into the carbon-fiber shells and incorporate threaded inserts for attaching the wing to the chassis.

While the team has used these ribs for years, they have redesigned for this season to accommodate changes in the aerodynamic shape of the wings. Using INTAMSUITE™ NEO and the 3D printing technology, they conducted topology optimization to achieve the lightest possible geometry, resulting in an organic shape that would not be possible to manufacture by milling.

%20(1).png?width=1000&height=667&name=%E6%9D%82%E5%BF%97%E6%A0%B7%E6%9C%BA%20(1)%20(1).png)

3D-Printed PEEK Stent Revolutionizes Nutcracker Syndrome Treatment

Whitepaper: Explore PEEK in FFF 3D Printing

©2026 INTAMSYS Technology. All Rights Reserved. Privacy Policy