此外,施耐德电气还利用 IDEX 技术,为工厂内部设备制造结构复杂的焊接工装夹具。通过将 PA6-CF 与可溶性支撑材料 SP3030 相结合,他们在不到六小时内就完成了这些零部件的制造,速度远超传统工艺。

作为全球能源管理与自动化领域的领导者,施耐德电气在一百多年来始终致力于优化资源配置、提升运营效率。在其位于保加利亚普罗夫迪夫的智能工厂中,施耐德电气专注于生产高品质电气元件,其中包括至关重要的小型断路器(MCB),用于防止过载和短路,确保电力系统的安全与可靠。

为简化生产流程并缩短交付周期,施耐德电气在数年前将**增材制造(AM)和熔融沉积成型(FFF)**技术引入其 3D 打印产线。2024 年 10 月,随着 INTAMSYS FUNMAT PRO 310 NEO 的引入,该工厂完成了一次重要升级,实现了关键零部件的内部制造,进一步提升了整体工作流程效率。

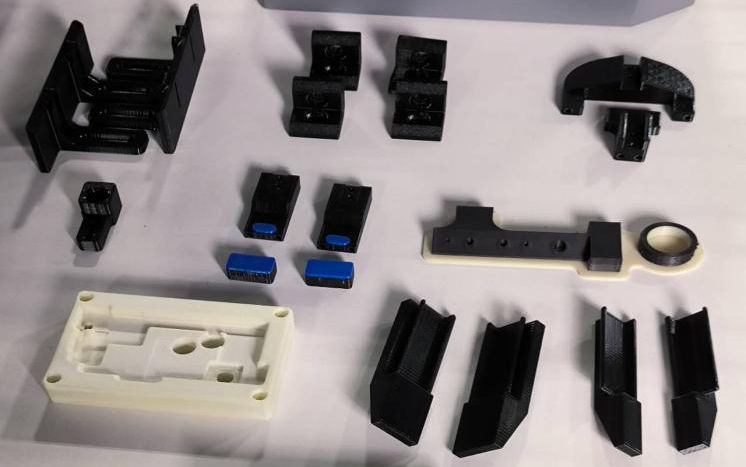

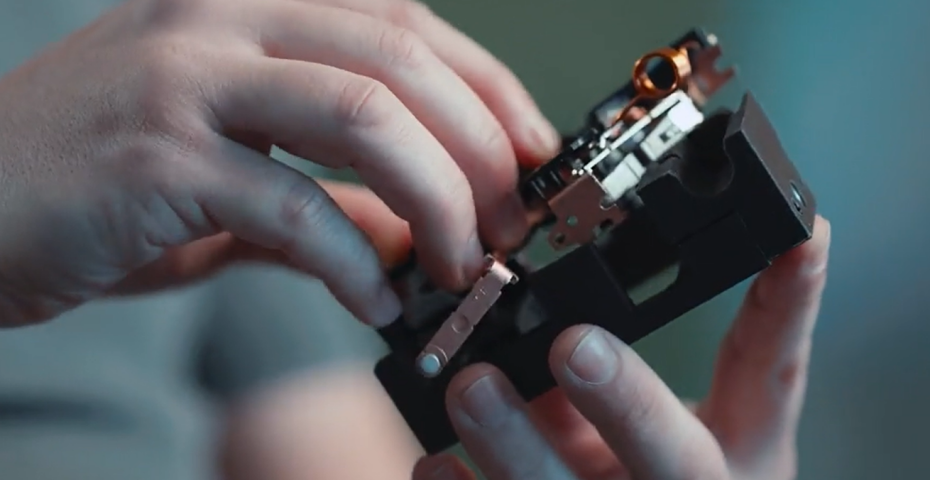

通过引入 3D 打印技术,该工厂如今已能够在内部完成生产线所需的全部机械部件制造。其中,FUNMAT PRO 310 NEO 在这一转型过程中发挥了关键作用,主要用于打印工装夹具,显著提升了生产流程效率。310 NEO 可搭配多种材料使用,包括 PC、PA6、PA12、PPA、PA6-CF 和 PPS,从而实现高强度、高质量零部件的生产。

We accompany our customers in a professional manner throughout the entire project - from planning and design to the prototype or the production of a complete series. Combining our 3D printing processes with conventional component processing, post-processing and surface refinement of the prototypes, small series or even a trade fair exhibit is our daily business. Since the company was founded in 1995, our experienced team in Gross-Gerau has made a name for itself well beyond the borders of the Rhine-Main area. We are one of the leading service providers for everything to do with 3D printing and have more than satisfied customers from a wide variety of industries - from the automotive and consumer goods industries to mechanical engineering and companies from the medical technology sector.

Alex Di Maglie

Managing Director, 4D Concepts

在引入 FUNMAT PRO 310 NEO 之前,施耐德电气由于依赖传统制造方式以及效率较低的 3D 打印方案,面临着明显的效率问题。功能原型和定制化零部件的生产周期过长,常常成为研发流程中的瓶颈。而注塑成型则进一步拉长了交付周期,有时甚至导致生产延误长达 三周或更久。因此,施耐德电气亟需一种更快速、更可靠的解决方案,以加速零部件生产并提升整体工作流程效率。

施耐德电气之所以选择 INTAMSYS FUNMAT PRO 310 NEO,主要看重其高速打印能力、广泛的材料兼容性以及工业级性能表现。对于同一零部件,310 NEO 可在仅需 2 小时内完成打印,而传统方案往往需要 12 至 15 小时,从而大幅加快了生产节奏。

该设备配备的自动调平系统和最高可达 100°C 的加热腔体,不仅简化了打印前的准备流程,也确保了始终如一的高质量打印效果。尤其是高腔温对 PC 等工程材料尤为有利,可有效防止大尺寸打印件翘曲,并提升 Z 方向强度,从而增强零部件的整体力学性能。

此外,310 NEO 采用开放式材料系统,可灵活适配多种材料。尽管如此,施耐德电气仍主要使用 INTAMSYS 原厂耗材,以获得经过优化的打印参数和更加稳定一致的打印质量。

我们更倾向于使用 INTAMSYS 生产的材料,因为 INTAMSUTE NEO 切片软件内置了经过优化的材料参数配置,能够确保每一次打印都获得理想的效果。

Kamen Vasilski

施耐德电气 维修工程师

IDEX 技术

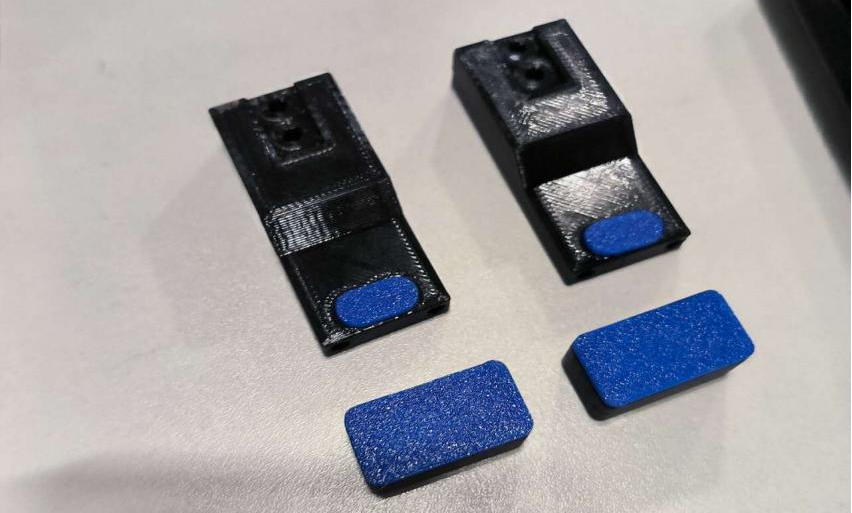

310 NEO 搭载的 IDEX(独立双喷头)技术,使施耐德电气能够在一次打印任务中使用多种材料,制造结构复杂的零部件。例如,团队设计了一款具备类橡胶特性的夹爪,用于防止零件在生产线上滑落。通过将柔性的 TPU95A 与结构材料 PETG 相结合,他们成功制造出兼具耐用性与高品质的零部件,从而保障生产流程的顺畅进行。

此外,施耐德电气还利用 IDEX 技术,为工厂内部设备制造结构复杂的焊接工装夹具。通过将 PA6-CF 与可溶性支撑材料 SP3030 相结合,他们在不到六小时内就完成了这些零部件的制造,速度远超传统工艺。

自引入 FUNMAT PRO 310 NEO 以来,施耐德电气的生产效率实现了显著提升,主要体现在以下几个方面:

打印时间大幅缩短:原本需要 12 至 15 小时 才能完成的零部件,如今仅需 2 小时 即可打印完成,显著加快了生产节奏。

研发周期显著缩短:更快的打印速度使团队能够更加高效地对工装夹具进行迭代和测试,大幅减少开发时间,加快原型制作与验证进程。

设计能力进一步拓展:借助 IDEX 技术,可在单次打印中实现多材料与复杂结构的制造,降低了对传统制造方式的依赖,使设计更加先进,并缩短原型开发周期。

稳定且高质量的打印表现:自动调平和加热腔体等功能确保了打印质量的一致性,并有效降低打印过程中出错的风险,使每一次打印都能获得高品质成品。

成本与资源优化:通过将更多生产环节转移至内部完成,施耐德电气有效降低了外包成本,提高了材料利用率,并进一步提升了整体运营效率。

INTAMSYS FUNMAT PRO 310 NEO 在施耐德电气位于保加利亚普罗夫迪夫的智能工厂中的应用,显著提升了生产效率、灵活性和成本节约能力。3D 打印技术的深度集成,正持续推动电气元件生产方式的创新。

随着获得智能工厂认证,施耐德电气计划进一步扩展其 3D 打印产线,提升零部件和备件的内部制造比例,从而进一步降低维护成本,并增强生产的自主性。

这一成功案例充分展示了 3D 打印在现代工业环境中的变革潜力,也有力证明了 INTAMSYS FUNMAT PRO 310 NEO 如何通过更高的效率与创新能力,重塑制造流程。

Most consumer-level FFF 3D printers cannot print brackets capable of supporting exceptionally heavy weights. Common filaments like PLA and ABS are durable enough for prototypes and low-impact applications, but it takes a much stronger material to guarantee high performance in the heat and humidity of Suriname.

During a military exercise in South America, crew members needed brackets to support a 20 kg signal amplifier so it could be mounted near the top of a 25-meter pole. This placement reduced the need for long cables and boosted the antenna signal. Without the necessary brackets on hand, the crew used an INTAMSYS printer to create them out of PEKK-CF, a high-performance material requiring extrusion temperatures of at least 350°C. Weaker materials would have buckled under the heavy weight and compromised safety.

A naval ship or submarine contains numerous valves for regulating pressure and fluid flows, controlling everything from fresh water to hydraulic systems. These valves have wheels that allow manual adjustments and are regularly removed for cleaning and maintenance. However, they sometimes break or get lost, necessitating spares.

Due to the diversity in valve wheel types and sizes, DMI workers have been using their INTAMSYS 3D printers to fabricate wheels on demand rather than carrying numerous prefabricated aluminum/steel spares. Valve wheels printed in high-strength materials are durable, resistant to overheating, and can even be installed permanently.

Ships and machines aren’t the only things that require maintenance on long missions. Crew members can suffer injuries in the field, and ships aren’t always within reach of a medical center.

DMI’s additive specialists have been collaborating with Radboud University Medical Center on a research project to develop custom orthotics. Using a mobile 3D scanning application developed by Belgian company Spentys, technicians can design and 3D print custom-fit orthotics to treat minor injuries. A variety of materials can be used, including PEKK, ABS, and PP. The devices can be adjusted over time with straps as the injury heals.

3D PRINTER

FUNMAT PRO 410

COST-EFFECTIVE

Print Larger, Print More

OPEN

Open-Sourced Filaments

©2026 INTAMSYS Technology. All Rights Reserved. Privacy Policy