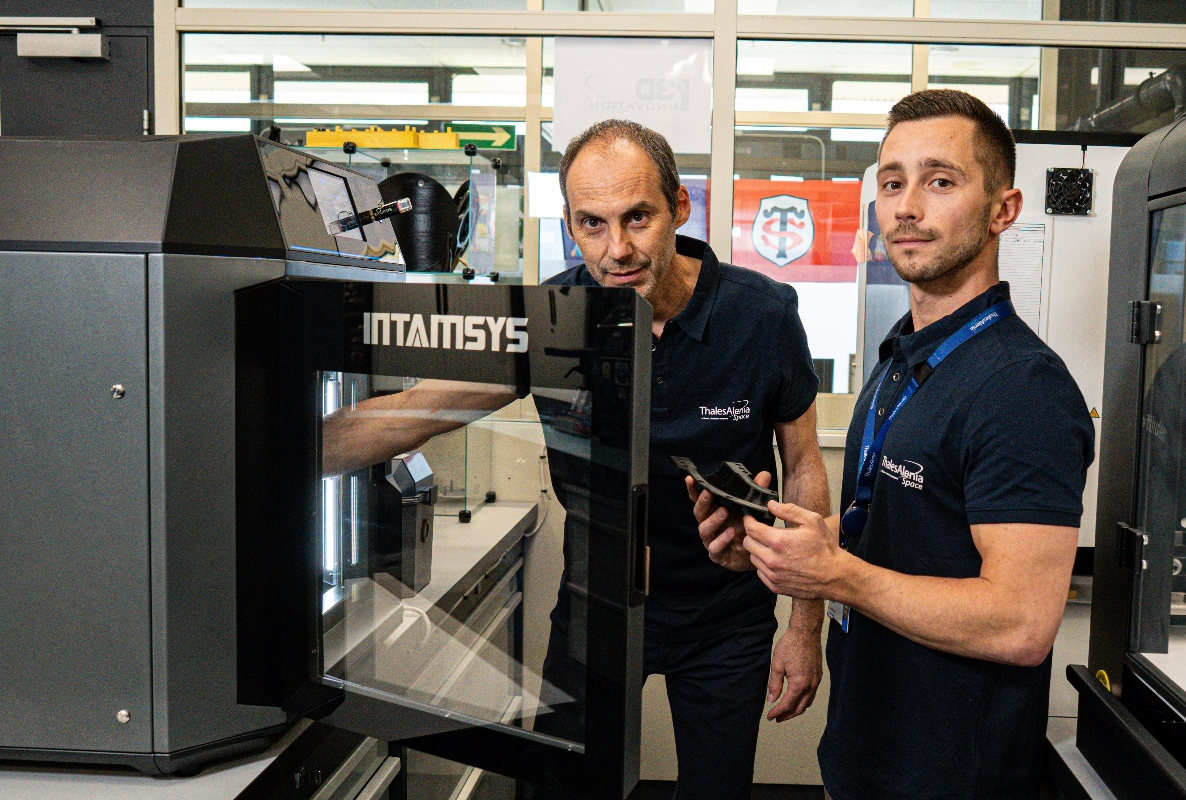

Thales Alenia Space 如何借助 FUNMAT PRO 310 NEO 实现规模化

Thales Alenia Space 是全球领先的卫星与航天系统工程企业,业务涵盖电信、地球观测与深空探索等多项任务,并在多个国家设有研发与制造基地,在塑造未来航天科技方面发挥着关键作用。在其位于法国图卢兹的最大研发制造中心,增材制造已成为创新的核心力量,为高要求应用提供更敏捷、更具成本优势的解决方案。

借助远铸智能高性能且灵活的增材制造解决方案——FUNMAT PRO 310 NEO,Thales Alenia Space 实现了 符合 ESD 标准的航天部件打印速度提升 3 倍、成本大幅下降,进一步推动了航天制造的效率与创新。

Thales Alenia Space 从 2018 年开始探索使用 3D 打印聚合物设备,并于 2021 年引入高温机型 FUNMAT PRO 410,用于处理包括 PEEK 在内的超高性能聚合物。然而,随着新的应用场景不断出现,尤其是需要满足 ESD 安全并承受最高 125°C 热环境的应用,团队意识到需要一种更敏捷、同时针对 PC-ESD 和 PA-ESD 等技术材料优化的解决方案。

我们将 FUNMAT PRO 410 专用于最技术型的材料处理。而对于 PC-ESD 和 PA-ESD 等其他高要求材料,我们需要更高速度、更灵活,并具备加热腔体和 IDEX 双喷头结构的系统——因此我们选择了 FUNMAT PRO 310 NEO。

Nicolas Cassé

Thales Alenia Space 聚合物 3D 打印技术负责人

自从引入 FUNMAT PRO 310 NEO 以来,Thales Alenia Space 在效率与成本方面均取得了显著提升。团队能够将打印速度提升至原来的 3 倍,同时将部分技术部件的制造成本降低 高达 90%。该设备配备 IDEX 双喷头,可同时打印多个小型零件,大幅提升产能。

作为一款为工程材料而设计的设备,FUNMAT PRO 310 NEO 采用加热腔体与加热平台,确保 PC-ESD 等材料在稳定环境下加工,尤其适用于紧迫周期下的快速生产。同时,INTAMSUITE NEO 的加入,使参数调节更加简化,并能兼容包括第三方材料在内的多种耗材,无需复杂校准,即可完成切换,显著优化工作流程。

借助这一组合方案,Thales Alenia Space 得以在不牺牲技术性能的前提下,实现小批量生产的规模化推进。

Thales Alenia Space 目前借助 FUNMAT PRO 310 NEO 打印多种航天级应用部件,包括:

卫星装配工装

电子器件的 ESD 防护包装

用于机械与热工验证的功能性原型

内部演示件及面向客户的展示模型

依托远铸智能的开放材料体系,团队可以灵活使用 PC-ESD、PETG-ESD 等多种工程材料,并能够在默认打印参数下取得出色效果。

Thales Alenia Space 也高度认可远铸智能及其本地合作伙伴 CADVISION 所提供的可靠支持与清晰的技术沟通。对技术与服务的双重信任,使团队不断扩大远铸智能系统在各类项目中的应用范围。

借助 FUNMAT PRO 310 NEO,Thales Alenia Space 构建了融合工业级性能、多材料适配及快速制造能力的增材制造流程。从 ESD 防护包装到航天功能工装,这款设备使团队能够满足严苛的技术需求,同时显著缩短交付周期并降低生产成本。

FUNMAT PRO 310 NEO 具备紧凑占地、开放材料体系与直观软件界面,非常适用于敏捷生产环境,特别是在工程材料应用与紧迫时间计划下的打印需求。结合本地团队的快速技术支持,远铸智能持续为关键航天制造应用提供可靠价值,成为值得信赖的技术合作伙伴。

After thorough research and benchmarking, WEERG chose INTAMSYS as their supplier. The INTAMSYS FUNMAT PRO 410 met all their requirements with features like a heated chamber, dual heated nozzles, and a heated filament chamber.

INTAMSYS offered one single solution that got it all:

We accompany our customers in a professional manner throughout the entire project - from planning and design to the prototype or the production of a complete series. Combining our 3D printing processes with conventional component processing, post-processing and surface refinement of the prototypes, small series or even a trade fair exhibit is our daily business. Since the company was founded in 1995, our experienced team in Gross-Gerau has made a name for itself well beyond the borders of the Rhine-Main area. We are one of the leading service providers for everything to do with 3D printing and have more than satisfied customers from a wide variety of industries - from the automotive and consumer goods industries to mechanical engineering and companies from the medical technology sector.

Alex Di Maglie

Managing Director, 4D Concepts

We were looking for printers that can print high-performance materials and run 24/7 on our production floor. INTAMSYS offered a robust printer, a nice aesthetic finish, and a true partnership.

Matteo

Founder & CEO, WEERG

The INTAMSYS FUNMAT PRO 410 has been a performant and reliable tool since day one. It allows us to process high-performance polymers that enable our customers to innovate with them in highly loaded, thermally challenging, and metal replacement applications. It gives us the confidence that is needed to print 24/7 unattended with long print jobs of 100+ hours. It redefines what can be achieved with FDM technology.

Fabio Trotti

3D R&D Manager, WEERG

3D PRINTER

FUNMAT PRO 410

COST-EFFECTIVE

Print Larger, Print More

OPEN

Open-Sourced Filaments

INTAMSYS has sponsored the GreenTeam with a FUNMAT HT 3D printer, INTAM™ filaments, and consultation services. The 3D printed parts from INTAMSYS are used in various subsystems of the car, including the battery system, braking system, and power electronics.

3D PRINTER

FUNMAT HT

COST EFFICIENCY

Lower Cost, Shorter Lead Times

MATERIAL SUPERIORITY

Versatile INTAM™ Polymers

The tank holder is a new part in this year´s racing car. The part is printed on the FUNMAT PRO 610HT with the material choice of ABS. For the driverless disciplines, the team uses pressurized air to activate the brakes in an emergency. This year, they changed the concept of how pressurized air is stored, which required a new mounting solution. The tank holder is designed to solve this challenge.

.png?width=807&height=410&name=Flap%20Ribs%20(2).png)

Other 3D printed parts, using the FUNMAT PRO 610HT and PC material, are the flap ribs that play a crucial role in the construction of the car’s side wing. These ribs are glued into the carbon-fiber shells and incorporate threaded inserts for attaching the wing to the chassis.

While the team has used these ribs for years, they have redesigned for this season to accommodate changes in the aerodynamic shape of the wings. Using INTAMSUITE™ NEO and the 3D printing technology, they conducted topology optimization to achieve the lightest possible geometry, resulting in an organic shape that would not be possible to manufacture by milling.

Get the latest news and trends

Webinar Recap: Industrial-Grade FFF 3D Printing Paves the Way for Mass Production of Humanoid Robots

©2026 INTAMSYS Technology. All Rights Reserved. Privacy Policy