How Thales Alenia Space Scaled with the FUNMAT PRO 310 NEO

Thales Alenia Space is a global leader in satellites and space systems engineering, serving missions across telecommunications, Earth observation, and exploration. With operations across multiple countries, the company plays a key role in shaping the future of space technologies. At its largest R&D and manufacturing center in Toulouse, France, additive manufacturing has become a cornerstone of innovation - enabling agile, cost effective solutions for demanding applications.

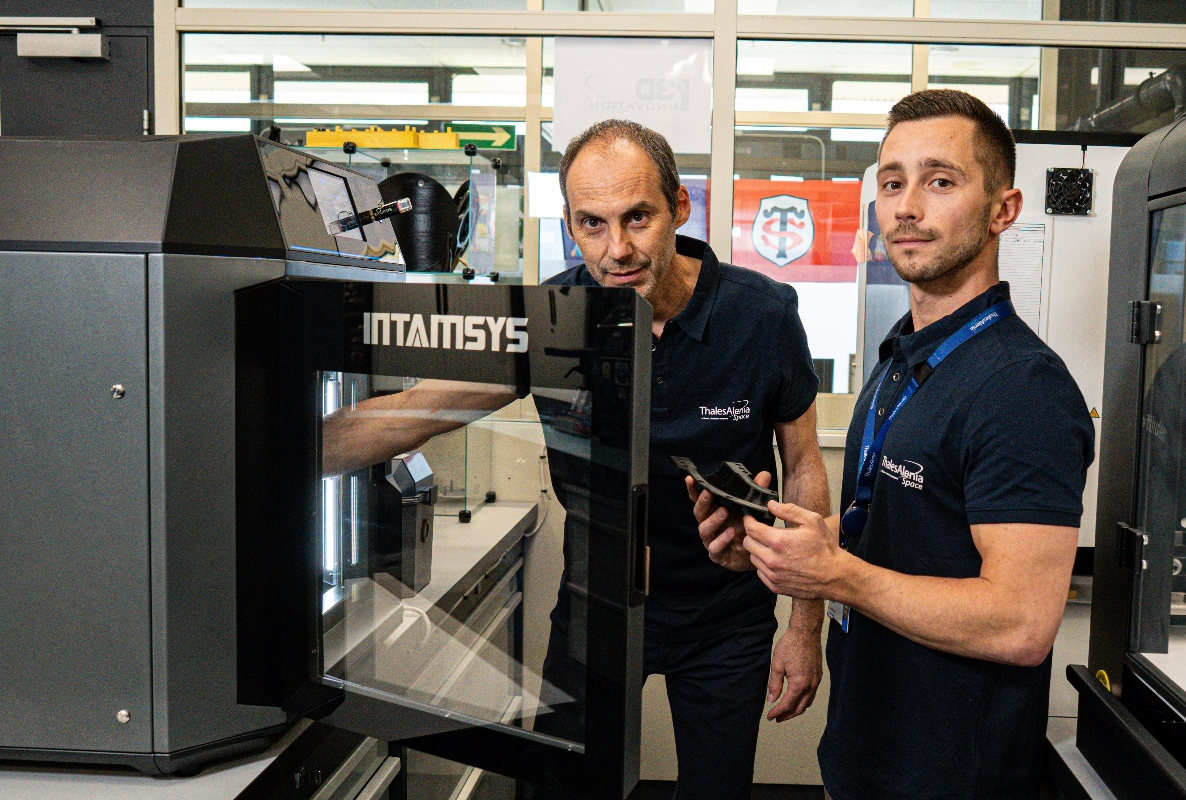

With INTAMSYS’s high-performance and agile additive solution - the FUNMAT PRO 310 NEO - Thales Alenia Space now prints ESD-compliant aerospace components 3x faster and at a fraction of the cost.

Thales Alenia Space began exploring the use of 3D printing polymer machines in 2018, later adopting the high-temperature FUNMAT PRO 410 in 2021 to process ultra-performance polymers such as PEEK. However, as new use cases emerged, particularly ESD-safe parts requiring heat resistance up to 125°C, the team identified a need for a more agile solution, optimized for technical materials like PC-ESD and PA-ESD.

We decided to dedicate the FUNMAT PRO 410 to our most technical materials. For other demanding materials like PC-ESD and PA-ESD, we needed a faster, more versatile system with a heated chamber and IDEX configuration - that’s why we chose the FUNMAT PRO 310 NEO.

Nicolas Cassé

Polymer 3D Printing Technical Responsible at Thales Alenia Space

Since adopting the FUNMAT PRO 310 NEO, Thales Alenia Space has achieved significant gains in both efficiency and cost-effectiveness. The team has been able to produce parts up to three times faster while also reducing the cost of certain technical components by as much as 90%. The printer’s dual extruder setup allows for the simultaneous production of multiple small parts, which greatly enhances throughput.

Designed for engineering materials, the FUNMAT PRO 310 NEO features a heated chamber and build plate that ensure stable processing conditions for polymers like PC-ESD. Its high-speed performance is especially valuable when working under time constraints. Additionally, the integration of INTAMSUITE NEO streamlines the workflow by simplifying parameter adjustments and enabling seamless compatibility with a wide range of filaments, including third-party materials, without the need for extensive calibration.

This setup empowers Thales Alenia Space to scale small-batch production without compromising on techinical performance.

Thales Alenia Space now relies on the FUNMAT PRO 310 NEO to print a range of aerospace-grade components:

With the open material system of INTAMSYS, the team successfully uses a wide range of materials - including PC-ESD, PETG-ESD, and other engineering filaments - achieving excellent results with the default print profiles.

Thales Alenia Space also credits the reliability of INTAMSYS and its local partner CADVISION for consistent support and clear technical communication. This trust in both technology and service has led the team to expand its use of INTAMSYS systems across projects.

With the integration of the FUNMAT PRO 310 NEO, Thales Alenia Space has strengthened its additive manufacturing workflows with a solution that combines industrial-grade performance, material versatility, and rapid production capabilities. From ESD-safe packaging to functional aerospace tooling, the 310 NEO enables teams to meet demanding technical requirements while significantly reducing lead times and production costs.

Its compact footprint, open material system, and intuitive software interface make it an ideal platform for agile production environments - especially when printing engineering-grade polymers under tight timelines. Backed by responsive local support, INTAMSYS continues to deliver value as a trusted technology partner in mission-critical aerospace manufacturing.

After thorough research and benchmarking, WEERG chose INTAMSYS as their supplier. The INTAMSYS FUNMAT PRO 410 met all their requirements with features like a heated chamber, dual heated nozzles, and a heated filament chamber.

INTAMSYS offered one single solution that got it all:

We accompany our customers in a professional manner throughout the entire project - from planning and design to the prototype or the production of a complete series. Combining our 3D printing processes with conventional component processing, post-processing and surface refinement of the prototypes, small series or even a trade fair exhibit is our daily business. Since the company was founded in 1995, our experienced team in Gross-Gerau has made a name for itself well beyond the borders of the Rhine-Main area. We are one of the leading service providers for everything to do with 3D printing and have more than satisfied customers from a wide variety of industries - from the automotive and consumer goods industries to mechanical engineering and companies from the medical technology sector.

Alex Di Maglie

Managing Director, 4D Concepts

We were looking for printers that can print high-performance materials and run 24/7 on our production floor. INTAMSYS offered a robust printer, a nice aesthetic finish, and a true partnership.

Matteo

Founder & CEO, WEERG

The INTAMSYS FUNMAT PRO 410 has been a performant and reliable tool since day one. It allows us to process high-performance polymers that enable our customers to innovate with them in highly loaded, thermally challenging, and metal replacement applications. It gives us the confidence that is needed to print 24/7 unattended with long print jobs of 100+ hours. It redefines what can be achieved with FDM technology.

Fabio Trotti

3D R&D Manager, WEERG

3D PRINTER

FUNMAT PRO 410

COST-EFFECTIVE

Print Larger, Print More

OPEN

Open-Sourced Filaments

INTAMSYS has sponsored the GreenTeam with a FUNMAT HT 3D printer, INTAM™ filaments, and consultation services. The 3D printed parts from INTAMSYS are used in various subsystems of the car, including the battery system, braking system, and power electronics.

3D PRINTER

FUNMAT HT

COST EFFICIENCY

Lower Cost, Shorter Lead Times

MATERIAL SUPERIORITY

Versatile INTAM™ Polymers

The tank holder is a new part in this year´s racing car. The part is printed on the FUNMAT PRO 610HT with the material choice of ABS. For the driverless disciplines, the team uses pressurized air to activate the brakes in an emergency. This year, they changed the concept of how pressurized air is stored, which required a new mounting solution. The tank holder is designed to solve this challenge.

.png?width=807&height=410&name=Flap%20Ribs%20(2).png)

Other 3D printed parts, using the FUNMAT PRO 610HT and PC material, are the flap ribs that play a crucial role in the construction of the car’s side wing. These ribs are glued into the carbon-fiber shells and incorporate threaded inserts for attaching the wing to the chassis.

While the team has used these ribs for years, they have redesigned for this season to accommodate changes in the aerodynamic shape of the wings. Using INTAMSUITE™ NEO and the 3D printing technology, they conducted topology optimization to achieve the lightest possible geometry, resulting in an organic shape that would not be possible to manufacture by milling.

Get the latest news and trends

Webinar Recap: Industrial-Grade FFF 3D Printing Paves the Way for Mass Production of Humanoid Robots

©2026 INTAMSYS Technology. All Rights Reserved. Privacy Policy